Authorized Dealer For

Hafer will design and build the custom case of your dreams.

You can buy 1 or 100!

A self-contained portable

beverage and snack bar.

A Hafer Original!

Hafer Case Builds

ATA Spec 300 Cases

Hafer Case Products carry

Limited Lifetime Warranties

Design and Construction - Hafer Case Never Cuts

Corners

The Hafer Case design staff works closely with customers to create

the optimal case for the equipment and contents to be protected.

Many criteria are considered including item weight, size, sensitivity,

value, storage conditions, shipping methods,

and more.

For Hafer ATA cases, all edging, corners, clamps, latches, handles

and hinges are machine riveted to ensure maximum strength and durability.

All fixed interior foam linings are spray glue coated, as opposed

to spot gluing. Spray glue ensures the integrity and longevity of the bond

to the case interior.

Hafer uses highest grade materials for ABS plastic and aluminum

walled cases. First quality hardware is used on Hafer cases and

is installed

and attached using machine riveting. Custom interiors are machined

from protective foam such as Polyethylene, Crosslink, Anti Static

varieties.

Hafer Case is the company you want to call when extraordinary case solutions

are absolutely required. Whatever it is you have to protect, Hafer

can build a case for it!

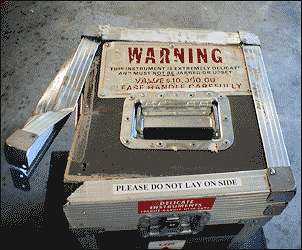

The

damaged brand-x case (pictured left) took a lickin' but couldn't

hold up to the day to day abuse. Unfortunately, the case maker used

fast, cheap, inferior construction methods and materials.

The metal corner angles used in the damaged case are referred to

in the industry as doubles, and are merely slipped over the edge

of the case wall and glued in place. Note that there are no rivets

in the corner angle. While this manufacturing method is faster and

cheaper, it leaves the case without integrity and the ability to

stand up to the abuses of real world action.

When comparing prices from different manufacturers, you must compare

the quality of construction and components as well. Less expensive

cases may cost you more in the long run in broken equipment,

repairs and replacements.

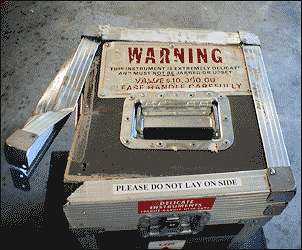

The

damaged brand-x case (pictured left) took a lickin' but couldn't

hold up to the day to day abuse. Unfortunately, the case maker used

fast, cheap, inferior construction methods and materials.

The

damaged brand-x case (pictured left) took a lickin' but couldn't

hold up to the day to day abuse. Unfortunately, the case maker used

fast, cheap, inferior construction methods and materials.